Most maintenance departments think they have a staffing problem when they actually have a visibility problem. A facilities director managing four office buildings recently calculated that his team could handle about 180 work orders monthly with their current headcount. In reality, they were completing only 127 while accumulating a backlog that grew 12% each quarter. The problem wasn’t lazy technicians or insufficient budget. It was a work order process built on email chains and spreadsheets that made prioritization guesswork and tracking nearly impossible.

This pattern repeats across industries. Maintenance teams struggle not because they lack skills or effort but because their work order systems create friction at every step. Requests get lost, priorities remain unclear, and critical information stays trapped in individual email inboxes instead of flowing to the people who need it.

Why Basic Work Order Tracking Fails Under Pressure

Many organizations start with simple solutions like shared spreadsheets or basic ticketing systems. These approaches work adequately when request volume is low and issues are straightforward. Once operations scale or complexity increases, the cracks become chasms.

Spreadsheets create information silos. When work orders live in Excel files, only one person can edit at a time. Updates happen sporadically. Technicians can’t access current information from the field. A property management company supporting 23 commercial buildings tried managing work orders via shared spreadsheets for 18 months. Their average work order sat in “pending” status for 6.3 days, mostly because nobody could tell which requests were actually being worked on versus which were forgotten.

Email chains lose critical context. Using email to manage work orders inevitably leads to fragmented conversations where half the relevant information lives in replies nobody remembers to check. Technicians arrive on-site without complete details. Follow-up questions create additional delays. One healthcare facility found that 41% of their work orders required at least one return visit because the initial request lacked sufficient information, and that context never made it to the assigned technician.

Manual processes don’t scale. A maintenance supervisor can mentally track 30-40 active work orders and juggle priorities through personal knowledge and frequent check-ins. That same supervisor with 100 active work orders faces an impossible cognitive load. Things slip through. Urgent requests get buried. The team spends more time managing the chaos than fixing actual problems.

Core Capabilities That Separate Effective Work Order Software

Not every work order management system delivers equal value. Some platforms merely digitize paper forms without changing underlying workflows. The solutions that genuinely transform maintenance operations share several critical capabilities.

Centralized intake from multiple channels. Employees need frictionless ways to submit requests regardless of where they’re working or what device they’re using. Effective work order software accepts submissions through web portals, dedicated mobile apps, email, and even text messages. Each request automatically enters the system with timestamps, requester information, and location data without manual data entry.

Automated assignment based on skills and availability. Advanced systems use technician certifications, current workload, and physical location to route work orders intelligently. Instead of a supervisor spending 30 minutes each morning delegating tasks, the system assigns work based on predefined business rules. A manufacturing facility with 200+ weekly work orders implemented automated assignment and recovered 12 hours of supervisor time weekly.

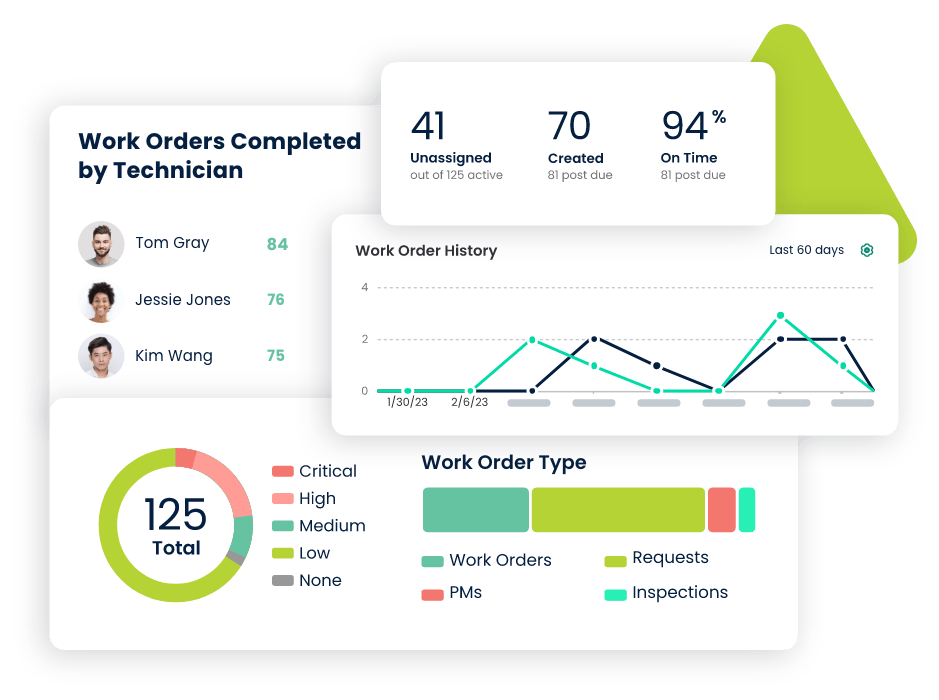

Real-time status visibility for all stakeholders. Requesters should be able to check their work order status without calling or emailing the maintenance office. Managers need dashboard views showing completion rates, backlog trends, and technician productivity. Work order software with role-based visibility eliminates constant status update requests and keeps everyone informed without creating communication overhead.

Comprehensive asset integration. When a technician opens a work order, they should immediately see relevant asset details including maintenance history, warranty information, technical specifications, and parts inventory levels. This context dramatically reduces diagnostic time and prevents repeat failures caused by incomplete repairs.

Mobile Access Changes the Game

The difference between desktop-only work order systems and mobile-enabled platforms is substantial. Mobile capabilities don’t just add convenience. They fundamentally change how maintenance work gets done.

Technicians receive work order notifications instantly on their phones, eliminating delays from physical paperwork distribution. They can review asset details and procedures while walking to the job site, arriving prepared with the right tools and parts. Photo and video capture lets them document conditions, attach evidence to work orders, and share visual information with supervisors or specialists without leaving the site.

Status updates happen in real-time as work progresses rather than hours later when the technician returns to their desk. This immediate feedback gives managers accurate visibility into team activity and helps them respond quickly when priorities shift or emergencies arise.

A hospitality company managing 18 properties implemented mobile work order software and measured the impact carefully. Their average work order completion time dropped from 3.7 days to 1.4 days. The improvement wasn’t because technicians worked faster. It came from eliminating administrative delays between request submission, assignment, technician notification, and status reporting.

Preventive Maintenance Integration Multiplies ROI

Work order management software delivers maximum value when it connects seamlessly with preventive maintenance scheduling. This integration ensures routine maintenance happens consistently instead of getting postponed by reactive work that feels more urgent.

Calendar-based triggers automatically generate work orders for time-based maintenance tasks like monthly filter changes, quarterly inspections, or annual certifications. Meter-based triggers create work orders when equipment reaches specific runtime hours or production cycles. Condition-based triggers can generate maintenance requests when sensor data indicates performance degradation.

The maintenance work order software tracks completion of these preventive tasks and adjusts future schedules based on actual conditions. If inspection data shows an asset is performing well beyond its standard service interval, the system can recommend extending the schedule to optimize labor allocation. Conversely, if an asset consistently needs service earlier than scheduled, the system flags it for interval adjustment or deeper investigation.

A food processing facility integrated their preventive maintenance program with their work order management system and saw dramatic results. Emergency breakdowns requiring overtime dropped 47% within six months. The same maintenance team, working regular hours, achieved significantly better equipment reliability simply because preventive work stopped falling through the cracks during busy periods.

Data-Driven Insights That Transform Operations

Every completed work order contains valuable information, but that data only becomes strategic intelligence when properly captured and analyzed. Work order software with robust reporting capabilities reveals patterns that drive continuous improvement.

Failure analysis identifies chronic problems. When specific equipment generates repeated work orders, that pattern signals a systemic issue requiring attention beyond routine repairs. Maybe the asset needs replacement, or perhaps operators need additional training, or environmental conditions are causing accelerated wear. Without software to track these patterns, maintenance teams keep responding to symptoms without addressing root causes.

Response time metrics reveal process bottlenecks. Analyzing the time between work order submission and technician assignment versus time between assignment and completion shows where delays actually occur. If work orders sit unassigned for hours but get completed quickly once assigned, the bottleneck is the assignment process, not technician availability. This insight directs improvement efforts where they’ll have the most impact.

Cost tracking per asset category supports strategic decisions. When work order management software accumulates labor and parts costs at the asset level over time, finance teams can make data-driven capital planning decisions. An asset costing $12,000 annually to maintain might warrant replacement when comparable new equipment costs $20,000 with a warranty that eliminates maintenance costs for three years.

Common Implementation Pitfalls to Avoid

Organizations often undermine work order software implementations through preventable mistakes. Understanding these pitfalls helps ensure your system delivers expected value.

Replicating broken workflows digitally. If your current paper-based work order process has six approval steps and unnecessary handoffs, simply automating those same steps won’t improve outcomes. Use implementation as an opportunity to streamline workflows and eliminate bureaucracy that doesn’t add genuine value.

Insufficient training and change management. Even the most intuitive work order software requires proper onboarding. When technicians and requesters don’t understand how to use the system effectively, they create workarounds that undermine adoption. A municipal facilities department saw only 41% system usage three months after launch because they provided minimal training and expected people to figure it out themselves.

Neglecting data cleanup before migration. Importing messy asset data, outdated location lists, and inaccurate equipment hierarchies into new work order software creates ongoing frustration. Take time before implementation to verify asset information, standardize naming conventions, and establish clear organizational structures. Clean data from day one prevents problems that are expensive and time-consuming to fix later.

Failing to define success metrics. Without baseline measurements and improvement targets, nobody knows whether the new system is actually delivering value. Establish clear metrics before implementation, such as average work order response time, completion rate, backlog size, and technician productivity. Track these metrics monthly and use them to guide system optimization and process refinement.

The Strategic Value Beyond Efficiency

Effective work order software delivers benefits that extend well beyond processing requests faster. The real transformation happens in how maintenance operations contribute to broader organizational goals.

When work order data flows into performance analytics, maintenance leaders can demonstrate their department’s impact with concrete metrics. Instead of vague claims about “keeping things running,” they show specific reductions in equipment downtime, measurable improvements in asset reliability, and documented cost savings from preventive maintenance that prevented expensive emergency repairs.

When work orders automatically generate from preventive maintenance schedules and IoT sensor alerts, maintenance shifts from reactive to predictive. Teams address potential failures before they cause production disruptions or safety hazards. This proactive approach reduces total maintenance costs while improving operational reliability.

When technicians have instant access to comprehensive work order history and asset information, they solve problems more thoroughly and make better repair-versus-replace decisions. The organization gets more value from its maintenance spend because work gets done right the first time instead of requiring multiple follow-up visits.

A regional healthcare system with 22 clinics transformed their facilities maintenance by implementing integrated work order software. Within nine months, patient-reported facility issues dropped 56% not because buildings improved overnight but because work orders got handled systematically instead of sporadically. Emergency maintenance costs fell 38% as preventive work orders reduced crisis situations. The maintenance department shifted from being viewed as a cost center to recognized as a strategic asset that directly supported patient satisfaction and operational efficiency.

Work order software transforms maintenance from chaotic firefighting into strategic asset management. The question isn’t whether to modernize but how quickly you can start realizing measurable improvements in response times, completion rates, and maintenance effectiveness.